Coding in Plastic

Agile Product Development for Physical Goods

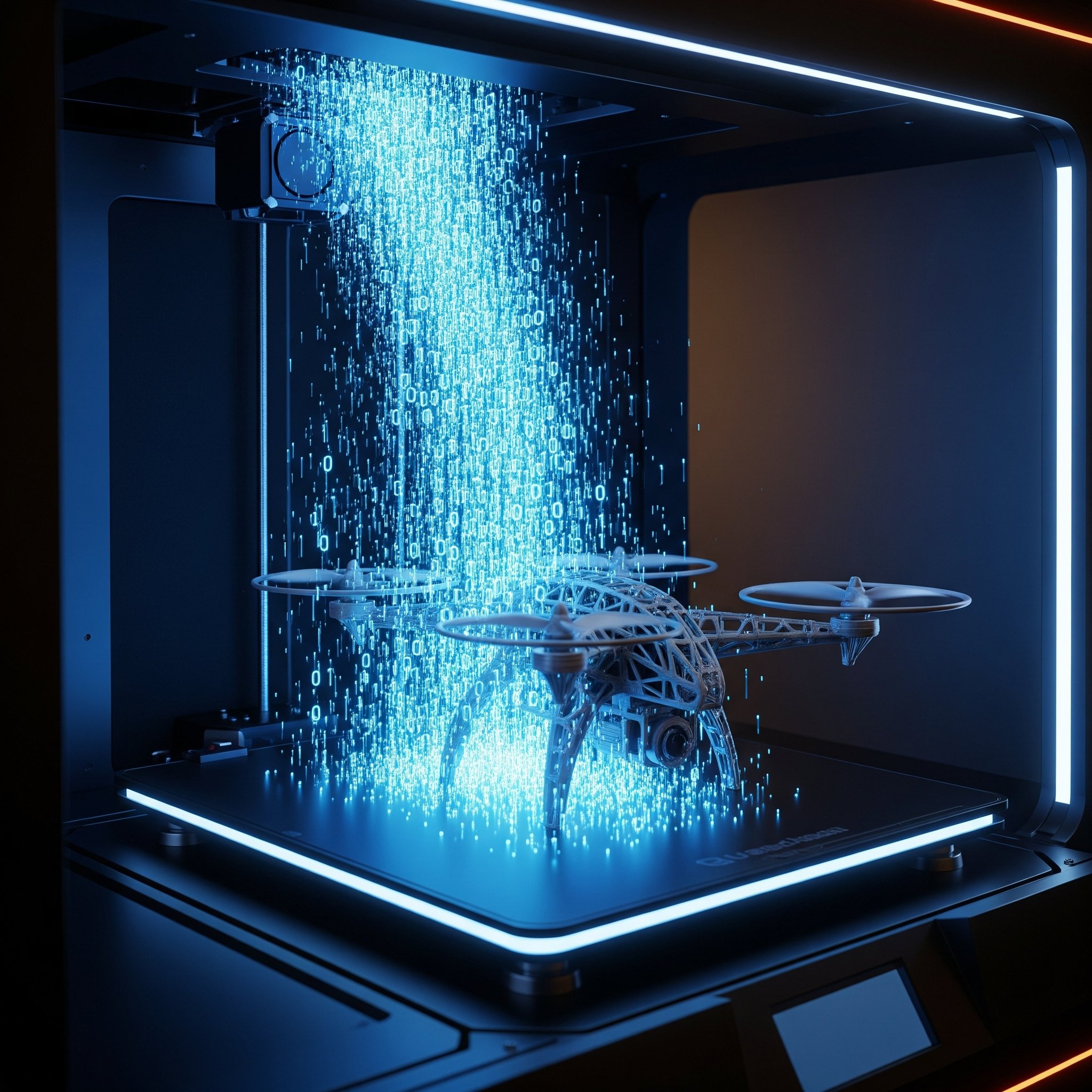

Image by Google Imagen

The war in Ukraine has shown how agile approaches, which have revolutionized software development, can do the same with hardware. Armed with computer-aided design (CAD), 3D printers, a sense of urgency, and a lot of thinking outside the box, Ukraine’s arms industry is adapting almost daily to meet the challenges of a constantly evolving battlefield. This is a perfect case study for organizations that produce physical products.

Agile emerged in the 1990s. Developers found that traditional methods weren't suitable for software development, as it didn't need expensive tools or big factories and could easily be adapted to customer needs and market changes. Many started moving away from the rigid waterfall model towards delivering small, functional parts of code that could be tested and improved quickly. This approach was officially outlined in the Agile Manifesto in 2001, when 17 developers gathered in Utah to share ideas and practices. Since then, Agile, along with related frameworks like Scrum and SAFe, has become widely adopted in the software industry.

Meanwhile, due to the constraints of manufacturing physical products, such as high startup costs in tooling, assembly lines, and minimum production quantities, the adoption of Agile methods was limited, and manufacturing was largely left to continue with more traditional waterfall development frameworks.

Around the same time as the Agile movement, a new technology called additive manufacturing was developing, which, years later, would enable Agile methods for developing physical products. The first 3D printers appeared in the late 1980s, but they only became widely used in the 2010s due to issues with cost, quality, and speed, primarily serving as tools for prototyping. However, current advances like Stereolithography (SLA), Digital Light Processing (DLP), Selective Laser Sintering (SLS), and Selective Laser Melting (SLM) now allow us to produce high-quality parts, including aircraft-grade. Since this process does not require costly steel molds, it supports complex designs and Agile product development, as the underlying CAD files can be easily updated like mobile apps.

Dustless Technologies, where I established and led product management, faced some serious challenges at the height of the COVID pandemic when our product components were stuck on ships for months outside the port of Los Angeles, showing how vulnerable global supply chains could be. While we had been using CAD and 3D printers for design and prototyping for years, the advances in technology and materials had made serial additive production and agile product development possible for our physical products. We saw an opportunity to redefine how we developed and produced our products.

Our past products needed months of detailed planning and development, and then required tens of thousands of dollars in injection tooling to launch. Worse, if a problem arose after launch or sales did not materialize as expected, fixing design flaws and unsaleable inventories cost even more. With our inventory problems, we began to look more closely at our 3D printers. We picked a concept from our product roadmap and started our Agile product development journey.

Pivoting to additive-driven Agile development allowed us to take a page from software development and run with it. We identified a need, created cross-functional teams, brainstormed a solution, created a minimum viable product (MVP), tested with real users/launched, evaluated, refined, and relaunched. We didn’t need to identify and solve every customer need at once; we could iterate just like with a phone app, adding other features or perfecting the design as we gained user insights. Modifications were as simple as inserting a line of code. We opened the CAD file, made the change, added a version number, and sent it to production. The updated product was in our users’ hands in weeks, not months. The result was the DustBuddie for Demo Hammers, a dust collection shroud for jackhammers and hammer drills printed from a flexible photo resin.

Our new process cut development times by 75% and costs by tens of thousands of dollars.

Our agile-additive process also improved inventory control. With traditional injection molding, the manufacturer required minimum orders of thousands of pieces. If there was a problem with the part or sales didn’t meet expectations, we ended up with useless inventory and financial losses. Our new approach allowed for either permanent additive production or, possibly, "bridge manufacturing," where we could start with additive manufacturing while we perfected the product and demand grew before having to consider injection molding tooling to take advantage of economies of scale and faster production times.

The flexibility of additive manufacturing also allowed for true just-in-time inventory management. This meant we could create products as needed, either in-house or through print farms, with smaller order sizes and lower costs. If a product didn’t succeed, we avoided excess inventory, and the printer resin could be used for more successful products. If a product did succeed, we could gradually increase production based on demand until it made sense to switch to traditional injection molding.

The success of this approach led to the birth of a new partner company, Merit3D, which provides design and additive manufacturing services for companies with new or constantly changing products and especially for those that want to bring product manufacturing back to the U.S.

The Customer-Led Innovations Consulting team includes experts and partners, like Merit3D, in agile development and additive manufacturing. Let us help you get your physical (or digital) product off the ground faster without the huge investment and risk of expensive tooling, while adding the ability to easily adjust and pivot to meet evolving customer demands. Click on the Free 1-Hour Consultation button at the top of the page to get started.